GRANDE STONEWARE presents TERRAZZO

This boutique terrazzo seminato collection is an industry leading surface covering. Expertly made with years of production experience, TERRAZZO delivers unrivalled beauty and product innovation. The cutting-edge manufacturing process and material reliability are paired with style and aesthetics, helping to create a uniquely bold ambiance.

Please read below for an overview and further details regarding TERRAZZO panels.

Origins & History

While “terrazzo” is an Italian word meaning “terrace”, the origin of this material dates back thousands of years, with its modern form evolving from resourceful Renaissance-era artisans.

Ancient Roots: Early “terrazzo-like” floors date to 9,000 BC in Turkey. Romans later used pavimentum sectile (marble fragments in clay).

Venetian Renaissance: Modern terrazzo was perfected 500 years ago by Italian artisans who upcycled marble scraps into “terraces” (terrazzo), using goat’s milk as a sealer.

Modern Shift: The 1920s saw electric grinders and metal dividers, while the 1970s introduced epoxy resins, allowing for thinner, lighter slabs.

Key Characteristics

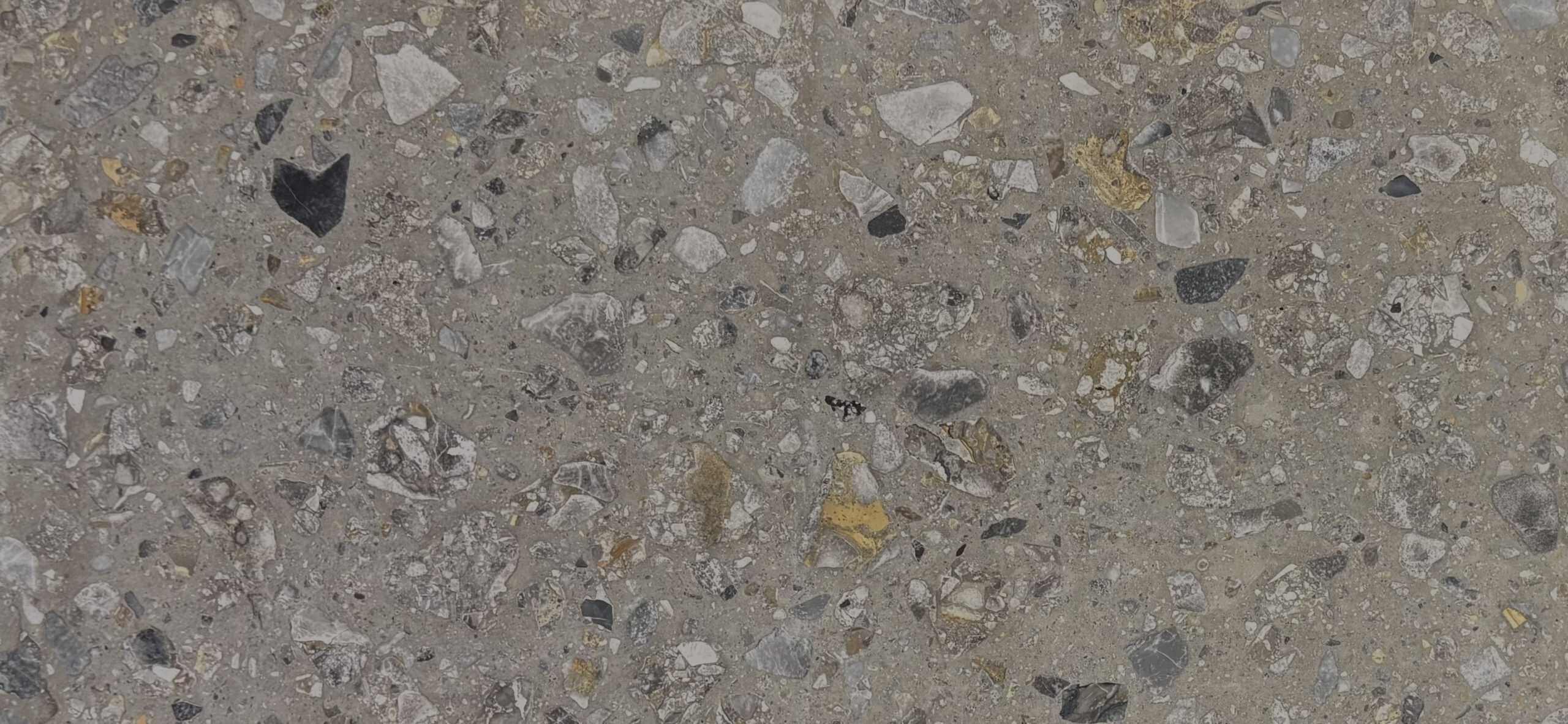

Composition: Aggregates (marble, quartz, glass, or metal) set in either Epoxy Resin (lightweight, non-porous) or Cement (UV-stable, ideal for outdoors).

Performance: Highly impact-resistant, hygienic and can be professionally re-polished if worn.

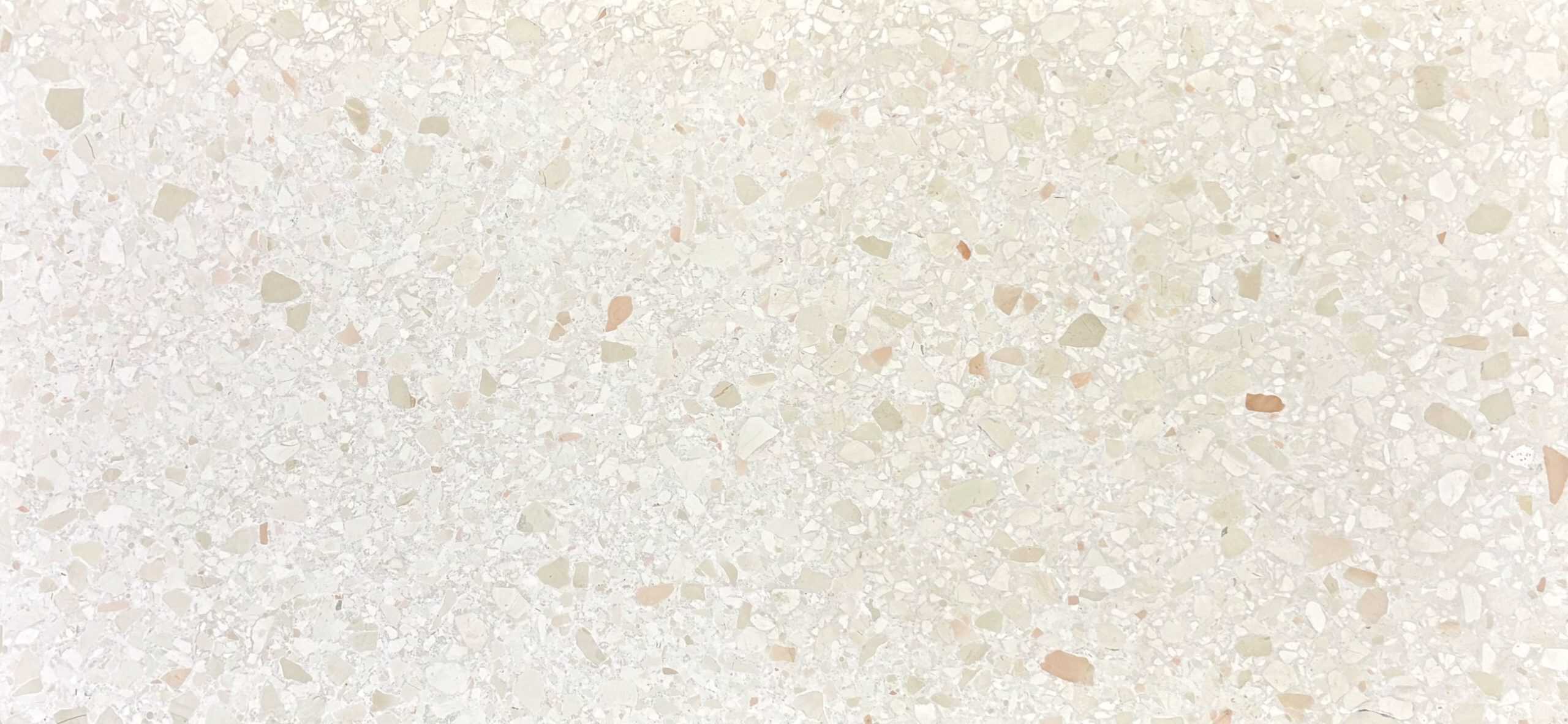

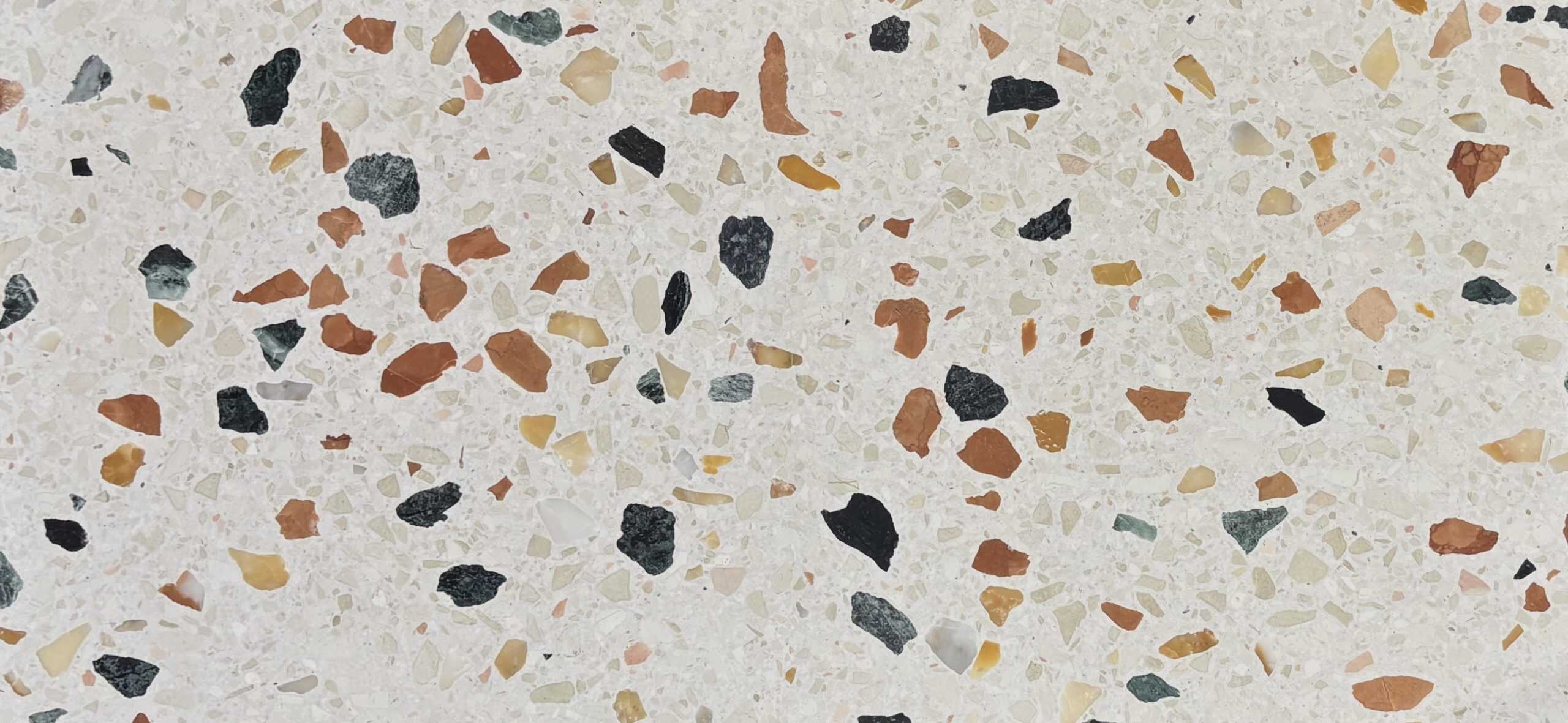

Customizable Patterns: By varying the size and colour of the chips (aggregates) and the pigment of the binder, designers can create anything from minimalist “micro-terrazzo” to bold “ceppo-style” slabs with oversized fragments.

Diverse Finishes: Slabs are available in honed (matte), polished (high gloss), or brushed/leathered textures.

Durability: Terrazzo is one of the toughest surface materials available, highly resistant to impacts, scratches, and heavy foot traffic.

Thickness: Slabs for countertops are typically 20mm to 30mm thick.

Hygienic Properties: Epoxy-based terrazzo is non-porous and naturally resistant to bacteria, mould, and mildew, making it ideal for healthcare and food preparation environments.

Sustainability: Terrazzo is often considered the original “green” surface covering. It remains a leader in sustainability because it typically contains 70% to 90% recycled content, such as stone offcuts and post-consumer glass. Its extreme longevity—often lasting the entire lifespan of a building—further reduces its environmental impact.

Eco-Friendly Design: Slabs often contain up to 70–90% recycled content, helping projects achieve LEED certification.

Colour Palettes: Current trends lean toward lavish warm earth tones and “Mediterranean-inspired” casual luxury, moving away from colder industrial greys.

Manufacturing Process

Mixing: Aggregates are blended with pigments and a binder (epoxy or cement).

Casting: The mix is poured into slab moulds or large blocks and compacted via vibration/vacuum to remove air.

Curing & Slicing: Epoxy cures in 24 hours; cement requires up to 28 days. Blocks are sliced into slabs using gang saws.

Polishing: Industrial diamond pads grind away the binder to reveal the decorative aggregates.

Grouting: Micro-voids are filled with a colour-matched slurry before a final seal.

Maintenance

Low Upkeep: Routine maintenance only requires sweeping and damp mopping with pH-neutral cleaners.

Refinish ability: Unlike many engineered surfaces, terrazzo can be professionally re-ground and re-polished if it becomes worn or scratched over decades of use.

Sealing: Cement-based slabs require regular sealing to prevent staining, whereas epoxy-based slabs are inherently impermeable.

Common Panel Applications

Interior: Kitchen benchtops and splashbacks, laundry/scullery benchtops and splashbacks, bathroom benchtops, bathroom walls and floors, staircases, fireplace and TV surrounds, dining tables and bespoke furniture.

Commercial: Multi residential kitchen and bathrooms benchtops, hygienic benchtops for hospitals and schools, healthcare and medical facilities, retail and hospitality spaces, food preparation areas, dining tables and bespoke furniture, High-traffic floor areas like airports and shopping centres, lobbies and common area flooring.

Please feel free to contact our team for further information.

Contact Details:

Email: info@grandestoneware.com

Phone: 08 9377 3385